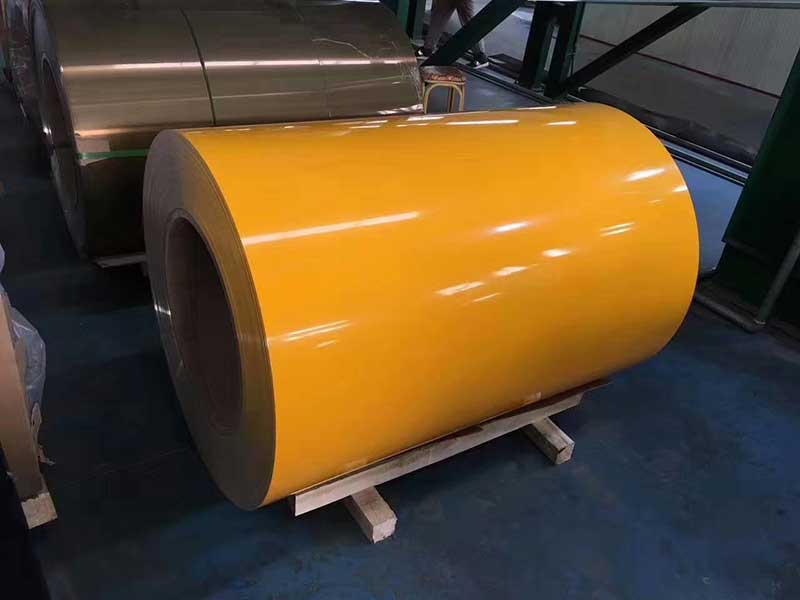

Organic Ceramic Color Coated Aluminum Coil Sheet, is the Henan Chalco Aluminum use of a water-based organic porcelain coating to produce a polymer alloy coating obtained by organic-inorganic hybridization of inorganic salts and organic substances containing silicon and fluorine, and is produced by a novel pre-rolling or spraying process. It is a new type of decorative material that is energy-saving and environmentally friendly,compared with ordinary solvent-based metal color-coated sheets, VOC emissions are reduced by more than 80% ,unrestricted emissions ,

combustion resistance etc level reaches the highest level of Al, and the gloss selection range is wider,the Organic Ceramic Color Coated Aluminum Coil Sheet has a gloss range of 5~95°, and the color is not limited, which can meet various color imagination requirements.

1,The Specifications of Organic Ceramic Color Coated Aluminum Coil Sheet

2, The Characteristics of Organic Ceramic Color Coated Aluminum Coil Sheet

1) Organic Ceramic Color Coated Aluminum Coil Sheet has the advantages of controllable range of gloss, high strength, high hardness, scratch resistance, high temperature resistance, acid corrosion resistance, high flame retardancy, aging resistance, self-cleaning performance and large color selection space.

2) Fire resistance: The resistance to combustion reaches the A1 level detected by the National Building Materials Quality Testing Center;

3) Low temperature drying: the temperature and time can be adjusted in the range of 170°C ~ 200°C for baking;

4) No harmful emissions: through ROHS, REACH requirements;

5) Strong functionality: anti-graffiti, anti-static, anti-mildew, anti-stone attack, surface energy can reach 25mN/m or less;

6) Diversified construction: mechanical coating (electrostatic, reciprocating machine), manual spraying, roller coating;

7) Excellent aging: the gloss-proof artificial accelerated aging 3000-hour comprehensive rating passed.

3, The Application of Organic Ceramic Color Coated Aluminum Coil Sheet

Organic Ceramic Color Coated Aluminum Coil Sheet can be widely used in exterior wall decoration of high-rise buildings, interior architectural decoration, high-end residential buildings, villas and architectural decoration; can also be applied to home appliances, kitchen appliances, rail transit subway stations, tunnels, airports, trains Indoor and outdoor decoration of stations, train rooms, high-end building curtain walls, exhibition halls, stadiums etc places where people gather, with high temperature resistance, acid corrosion resistance, scratch resistance, high hardness, fire resistance, weather resistance and self-cleaning function.

combustion resistance etc level reaches the highest level of Al, and the gloss selection range is wider,the Organic Ceramic Color Coated Aluminum Coil Sheet has a gloss range of 5~95°, and the color is not limited, which can meet various color imagination requirements.

1,The Specifications of Organic Ceramic Color Coated Aluminum Coil Sheet

| Coating type | water-based organic porcelain coating |

| Alloy | 1050,1060,1100,3003,3105,5052,5454,5005,5754,etc |

| Temper | H16,H24,etc |

|

Aluminum Coil Sheet Thickness |

0.2-1.6mm |

|

Aluminum Coil Sheet Width |

600-1850mm |

|

Aluminum Coil Sheet Length |

According to customer requirements |

| Coating thickness | Single coating (4-20 microns), double coating (25-28 microns), 3 coating (35-38 microns) |

| Colors | Color is not limited, can be adjusted any color according to customer needs |

| Gloss | 5~95° |

| Pencil hardness | ≥5H |

| Adhesion | 0-1 |

| Self-cleaning | Have |

| Fire resistance | A1 |

| Acid resistance | Good |

| Alkali resistance | Good |

| Aging resistance | Excellent |

|

Heat and humidity resistance |

Excellent |

| Salt spray resistance | Excellent |

|

Tobacco-producing tobacco grading |

AQl |

2, The Characteristics of Organic Ceramic Color Coated Aluminum Coil Sheet

1) Organic Ceramic Color Coated Aluminum Coil Sheet has the advantages of controllable range of gloss, high strength, high hardness, scratch resistance, high temperature resistance, acid corrosion resistance, high flame retardancy, aging resistance, self-cleaning performance and large color selection space.

2) Fire resistance: The resistance to combustion reaches the A1 level detected by the National Building Materials Quality Testing Center;

3) Low temperature drying: the temperature and time can be adjusted in the range of 170°C ~ 200°C for baking;

4) No harmful emissions: through ROHS, REACH requirements;

5) Strong functionality: anti-graffiti, anti-static, anti-mildew, anti-stone attack, surface energy can reach 25mN/m or less;

6) Diversified construction: mechanical coating (electrostatic, reciprocating machine), manual spraying, roller coating;

7) Excellent aging: the gloss-proof artificial accelerated aging 3000-hour comprehensive rating passed.

3, The Application of Organic Ceramic Color Coated Aluminum Coil Sheet

Organic Ceramic Color Coated Aluminum Coil Sheet can be widely used in exterior wall decoration of high-rise buildings, interior architectural decoration, high-end residential buildings, villas and architectural decoration; can also be applied to home appliances, kitchen appliances, rail transit subway stations, tunnels, airports, trains Indoor and outdoor decoration of stations, train rooms, high-end building curtain walls, exhibition halls, stadiums etc places where people gather, with high temperature resistance, acid corrosion resistance, scratch resistance, high hardness, fire resistance, weather resistance and self-cleaning function.