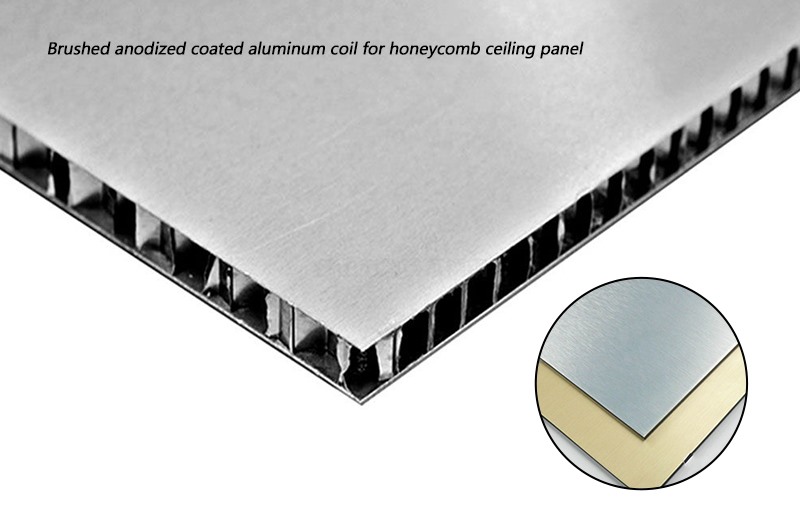

Brushed anodized coated aluminum coil for honeycomb ceiling panel is the manufacturing process of repeatedly scraping the aluminum plate out of the line with sandpaper. The main process of the process is divided into three parts: deesterification, sand mill, and water washing. In the aluminum sheet drawing process, the special film technology after anodizing can make a film layer containing the metal component on the surface of the aluminum sheet, and clearly show every fine wire mark, so that the metal matte shines with fine hair.

Silky sheen Brushed anodized coated aluminum coil for honeycomb ceiling panel In recent years, more and more metal shells of aluminum sheet products have used metal wire drawing technology to play a beautiful and anti-erosion role. Make products with elements of fashion and technology. This is one of the reasons why the craft is so popular. ,