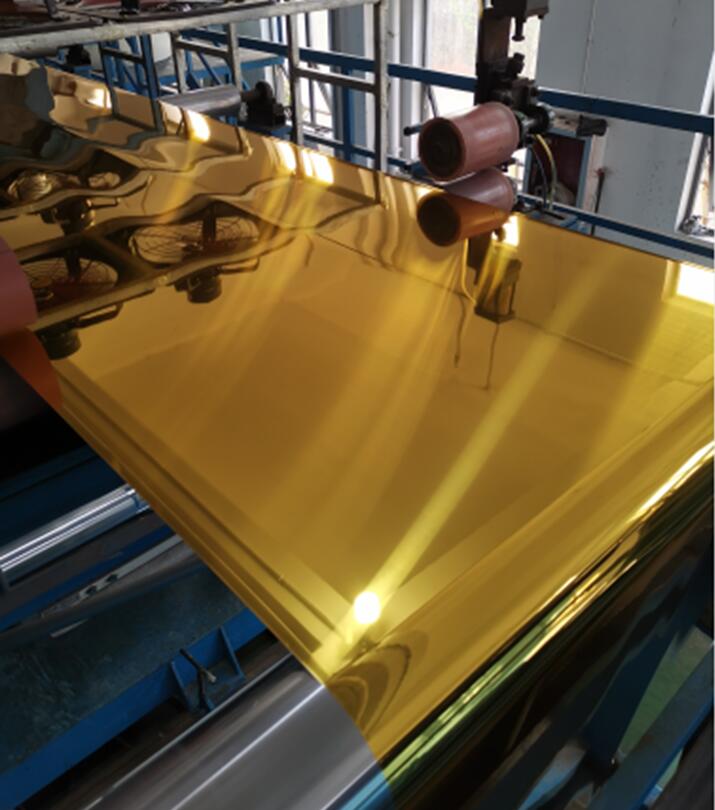

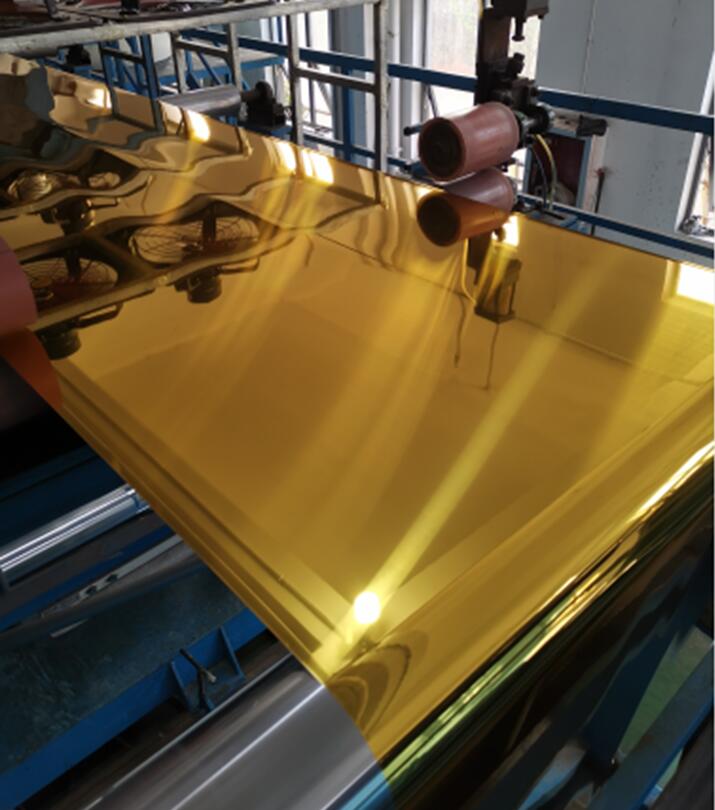

Brushed copper color aluminum sheet

News | 2021-08-06 17:38

Brushed copper color aluminum sheet is light in texture, has good plasticity and ductility, and is favored by large-scale projects.

Brushed copper color aluminum sheet is a manufacturing process in which the aluminum sheet is repeatedly scraped out of lines with sandpaper. The main process of the process is divided into three parts: de-esterification, sand mill, and water washing. In the aluminum sheet wire drawing process, the special coating technology after anodizing can make the surface of the aluminum sheet generate a coating layer containing the metal component, clearly showing every fine wire mark, so that the metal matte is full of fine hair. Silk luster. In recent years, more and more metal shells of aluminum plate products have used the metal wire drawing process to achieve aesthetics and corrosion resistance. Make the product have both fashion and technology elements. This is one of the reasons why this process is so popular.

Brushed copper color aluminum sheet

Brushed copper color aluminum sheet

Commonly used 3003/3004/3105/1100

Grey color aluminum sheet

Aluminum surface width: 1240mm/1250mm/1520mm/1600mm is commonly used for the panel, according to customer requirements;

Grey color aluminum sheet panel thickness: 1.0mm or more; the back plate is about 0.65mm, generally 0.5mm or more

Brushed copper color aluminum sheet

It is widely used in lighting reflectors and lamp decorations, solar heat collection and reflective materials, interior architectural decoration, exterior wall decoration, household appliances panels, electronic product shells, furniture kitchens, interior and exterior decoration of automobiles, signs, logos, luggage, jewelry boxes, etc. field.