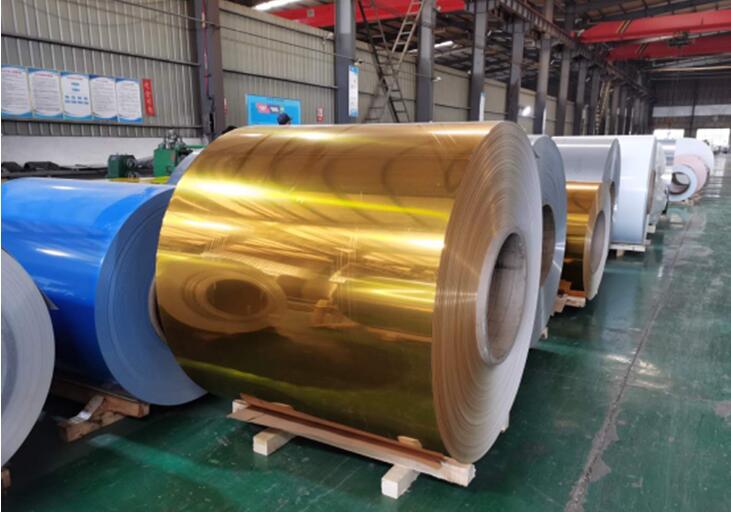

The process of roll coating aluminum sheet is as follows:

Roll coating aluminum sheet is a coating roller as the carrier of the coating. The coating forms a certain thickness of wet film on the surface of the coating roller, and the coating roller is in contact with the object during rotation to coat the coating on the surface of the object. . roll coating aluminum sheet is suitable for the coating of flat metal sheets, especially for high-speed coating of metal coils. Roll coating requires that the coating has good leveling, wettability and adhesion, a certain degree of hardness, flexibility and abrasion resistance, and has good weather resistance and stain resistance, and the baking and curing speed is fast.

Roll coating aluminum sheet has the following characteristics:

①High-speed automatic coating operation, fast coating speed and high production efficiency. The line speed is generally above 60 m/min, and the highest can reach 244 m/min (currently, the coating line speed of domestic equipment is generally 10~60m/min) ;

②No paint mist is generated, and the paint utilization rate is close to 100%;

③Suitable for coatings of various viscosities, the thickness of the paint film can be accurately controlled, and the thickness is uniform;

④The front and back sides can be coated at the same time. Roll coating aluminum sheet is only suitable for flat coating, not suitable for other shapes to be coated. Because the roller coater adopts a unified coating recycling and recycling system, the amount of coating input is large, which is not suitable for multi-variety, small-batch production;